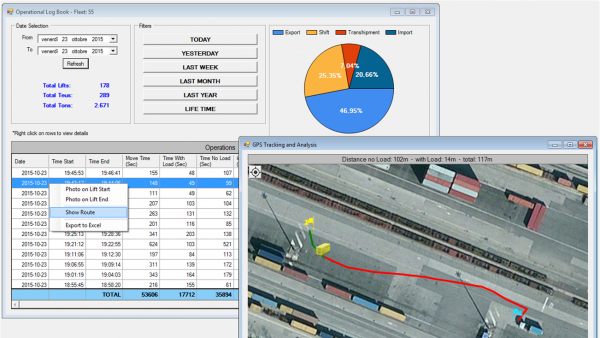

Our telemetry system allows to have a complete overview of the trend of the terminal activity, basing itself on the data generated by the sensors of the machines that are operating.

Basically this works as an IoT system, where starting from the data produced by the sensors installed on every machinery, you get real-time analysis of the whole activity of the terminal.

Neptuno

Modules

Dinamic Scale System

The Maritime Safety Committee (MSC) adopted amendments to SOLAS regulation VI/2, to require the mandatory verification of the gross mass of packed containers. Our solution will allow to easily and precisely accomplish this operation, in order to meet the limits required by the new sea legislation and enforce safety standards.

In fact, our solution will allow to communicate in real time the weight of each container to your TOS or ERP system.

Localization System

The system has a location module that lets you know the position of the containers inside the terminal and their movements. This will optimize the use of the lifting machineries, significantly reducing the number of movements. It is also possible to search the containers through the different criteria (BL, Booking, customer, date unloading / loading, IMO, Line, etc.).

The location will be displayed by the terminal layout that allows the visualization and graphical analysis of the containers’ status.

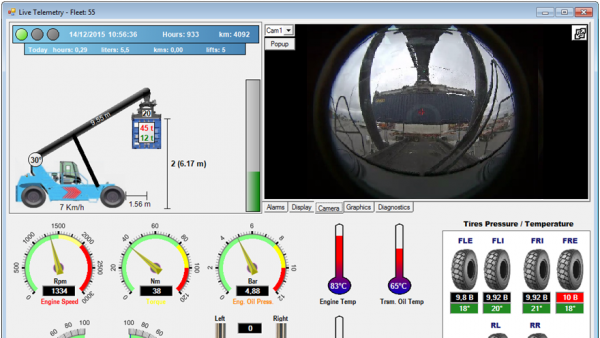

Maintenance Panel

The online diagnostic system provides information about the status of any asset remotely.

The system includes a complete alarms analysis module, which allows to study the state of the vehicle before, during and after the occurrence of an alarm.

This is a powerful tool that allows you not only to solve any incident, but also to understand the causes of anomalies, giving you the possibility to prevent any possible re-emergence of them.

Security System

Cameras On Board

It is possible to install, on any machinery, one or more cameras that allow you to record activities, having the point of view of those who perform the operations. At each movement, the image of the container will be stored at the time of the lift and its release.

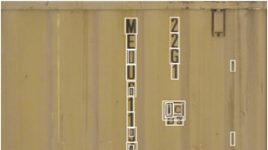

OCR

Our advanced OCR system, recognizes the number of containers handled and associates them to the location in the terminal. In this way you have an automatic and precise record of the position of each container in the terminal.